THE ROLE OF THE PRODUCTION PLANNER

In the era of digitalization, the planner is one of the most important roles in a production organization. An optimal production schedule equals optimal use of production resources, machines, lines, people. Properly planned tasks, synchronized plans for material supplies, cooperation, and retooling affect lower costs and higher profits. A production organization generates over 60% of its costs on production. The planner, their knowledge and experience, and the tools they use are therefore key to the results of the entire production organization.

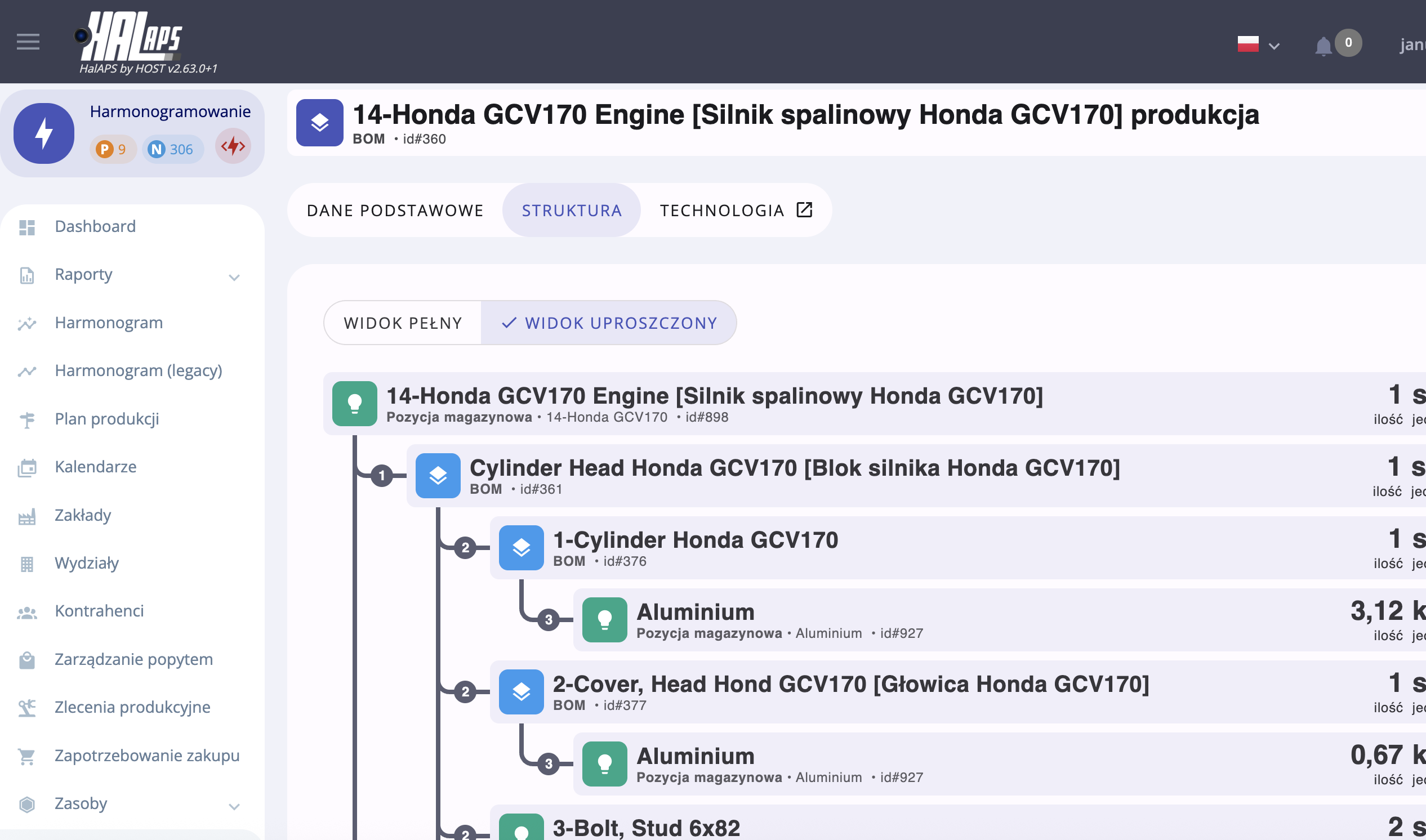

PLANNER SUPPORT TOOLS

A human cannot process a large amount of information faster than a computer. That is why the process of production planning and scheduling is supported by IT tools. Historically, the ERP system was created for this purpose, but we now know that it did not live up to the hopes placed in it and so many planners rely on MS Excel. Today, production planning and scheduling is supported by APS class systems. They specialize in fast scheduling of very complex production scenarios reflecting reality. Thanks to HAL APS, the impossible has become possible.

WHY APS

APS (Advanced Planning and Scheduling) is used to plan and schedule production, taking into account the much greater complexity of the technological process, much greater accuracy, speed of scheduling, creation of scenarios, and all this taking into account real production cases, as it really looks like.

MRP, CRP scheduling is insufficient in most companies today. It is based on infinite production capacities, resource overloads, does not balance people, tools, cannot create complex sequences for scheduling, has a relatively small arsenal of scheduling engine parameters, etc.

COORDINATED AREAS

The planner must coordinate all processes, at the interface with production processes. He cannot focus only on production, because the implementation of the production plan depends on the synchronization of activities in other business areas, such as:

Maintenance of traffic

Sales

Forecast

Marketing

Purchase

design and technology department

R&D / NPD

FREEZE PERIOD

How long should the production plan be frozen?

There is no single, right answer resulting from any good business practices. Businesses differ too much from each other. This requires in-depth analysis.

Production would like the longest possible freezing period, because stability in production is key to proper process organization, cost optimization and meeting deadlines. The sales department would like to handle every customer variability, here and now, and preferably yesterday. Purchasing also wants freezing because materials or raw materials are not lying on the shelves waiting for us.

OPTIMAL NUMBER OF PLANNERS

One planner or several? If there is one, what happens if someone gets sick, wants to go on vacation, has an accident? Can the organization afford to take such a risk in such a key area? In a large, multi-plant, geographically dispersed factory, one planner may not process a large amount of information about production disruptions and several planners are needed.

HOW MUCH DOES A PLANNER EARN?

A planner with knowledge and experience in planning, familiar with HAL APS, earns over EURO 5,000 per month. Often, a planner is also expected to work in ERP systems such as SAP, D365, Infor, Comarch, etc. and, in the case of foreign companies, to know a foreign language.

SHOULD YOU PLAN 100%

Manufacturing companies have to deal with unplanned events every day that make it difficult to implement the plan. Examples include excessive absenteeism, a truck with material ending up in a ditch, a machine failure, etc. The question is whether we should plan for 100% of the calendar time or leave a small buffer for unforeseen events. It all depends on the organization, but assuming you are not an automotive company, a small buffer can be used. When establishing it, it should be based on historical data so as not to inadvertently limit the production capacity of the plant.

ONE OR MORE SCHEDULES

Local optimization is harmful. These are the famous words of Ely Goldratt from Theory of Constraints. A few super optimized production schedules, e.g. for each department different, achieve the goals of a specific department, but destroy the goal of the plant as a whole. Only balancing the entire flow is supposed to bring benefits to the organization. You can start with the bottlenecks and adjust the rest to their work. This is a good strategy, proven in practice.

SHOULD THE PLANNER BE SUBJECT TO PRODUCTION?

No. The planner should report to management. Otherwise, production will force the planner to achieve its goals. They do not have to be, and most often are not, the goals of the plant. Such subordination sooner or later ends with support in manual control by top management.

S&OP DETAIL

S&OP is a form of medium and long-term planning on so-called thick blocks. This is planning on product groups, so by definition it is not precise or specific. It is planning on aggregated time areas, most often weeks. However, it has many advantages and in the case of production of own products, planning is necessary. However, until we break down the product groups into products, it does not contribute anything to the scheduling process.

HOW TO SCHEDULE WITHOUT DOCUMENTATION

In companies producing large-sized products such as ships, wagons, planes, tanks, structures, drilling platforms, etc., documentation can flow over time. Scheduling in such cases is possible and must be possible because production does not wait for a complete set of technical documentation but produces within the framework of the documentation provided and advance plans for purchasing critical materials.