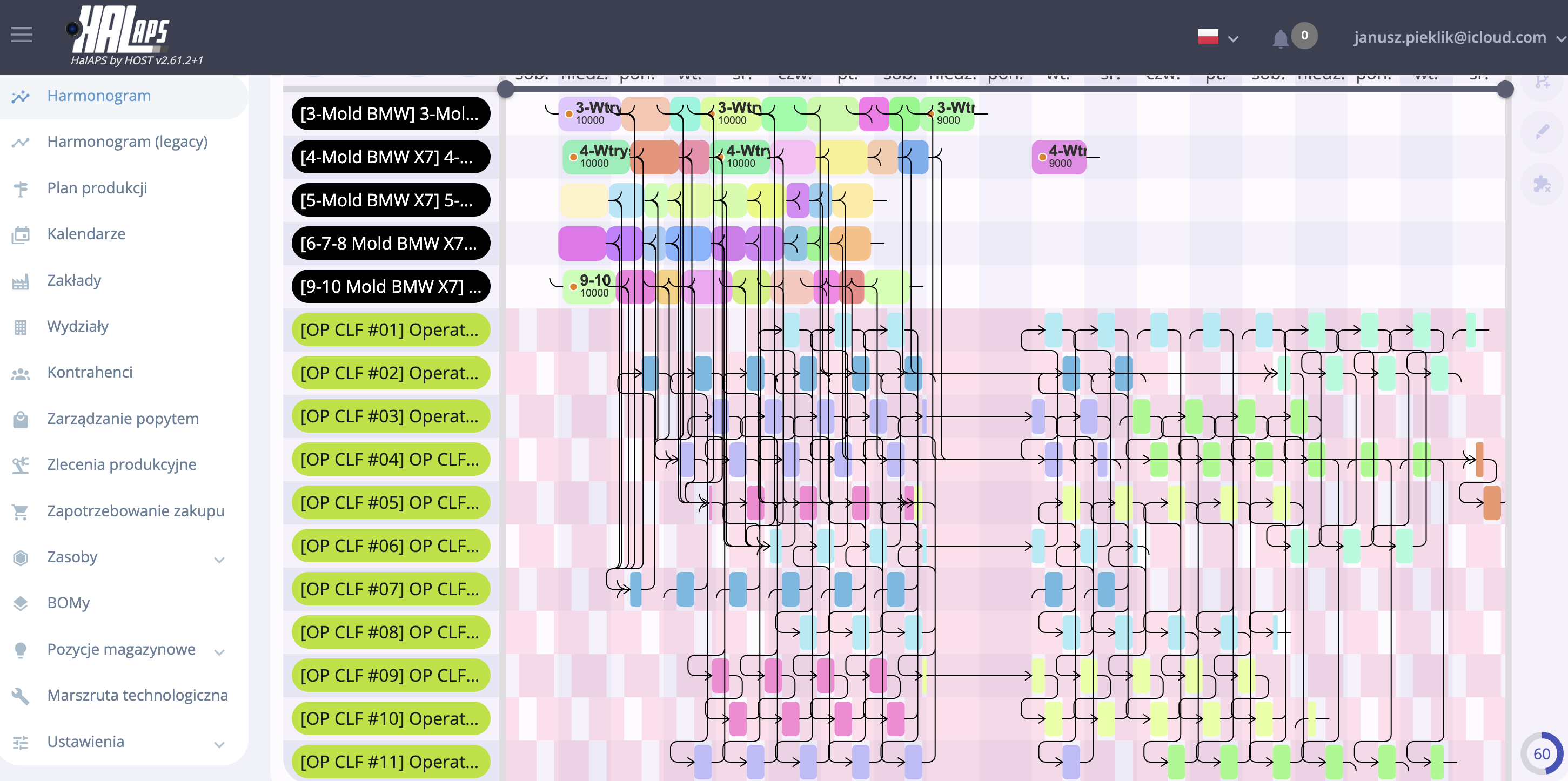

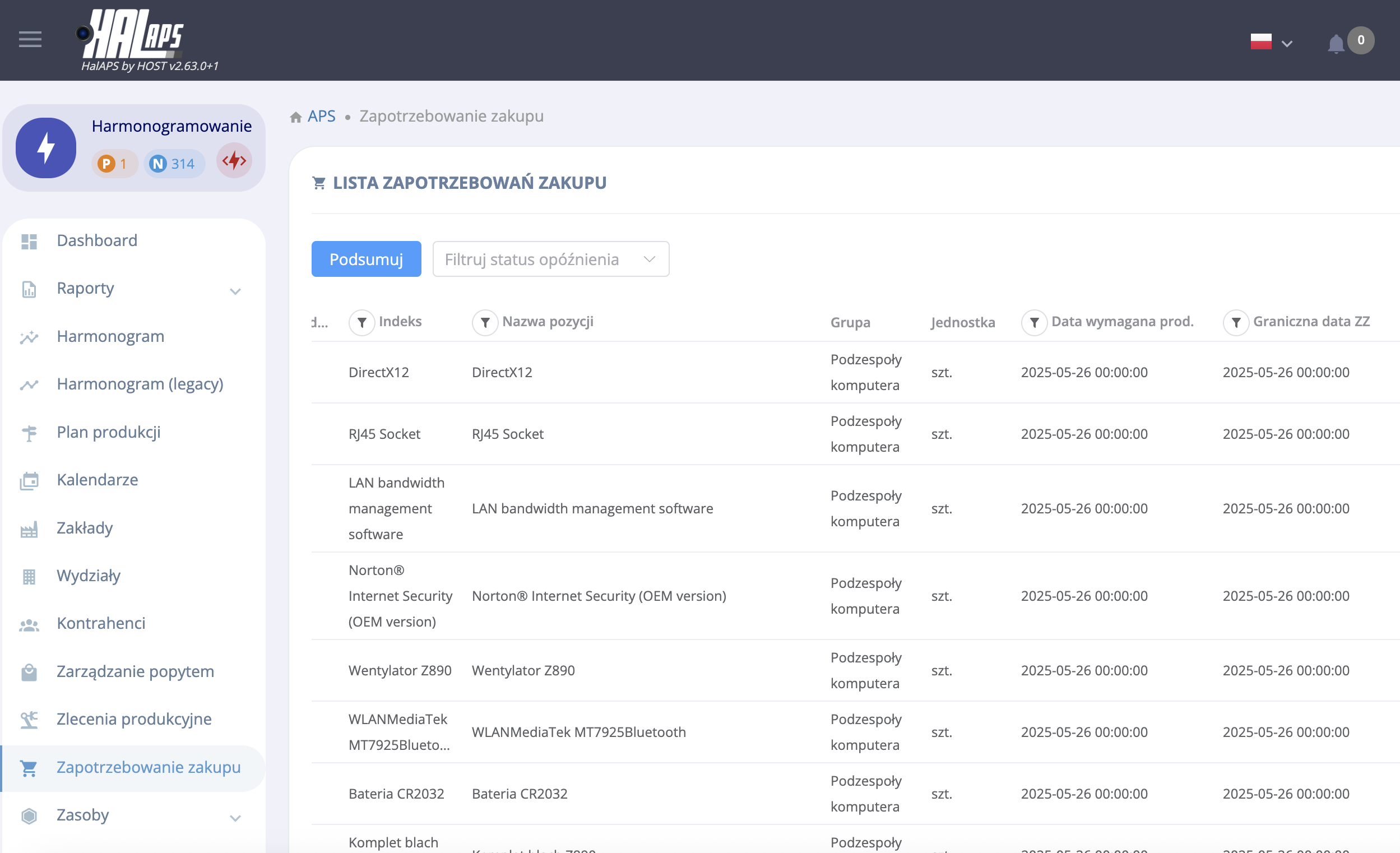

INTERFACE THAT SEDUCES WITH BEAUTY

The interface that captivates with its graphics, delights with its ergonomics and speed of operation. Modern, intuitive, minimizing the number of clicks. Designed with attention to the smallest details.

See for yourself, you can move from almost anywhere with one or two clicks.

Modern

Beautiful

Ergonomics

Eye-friendly

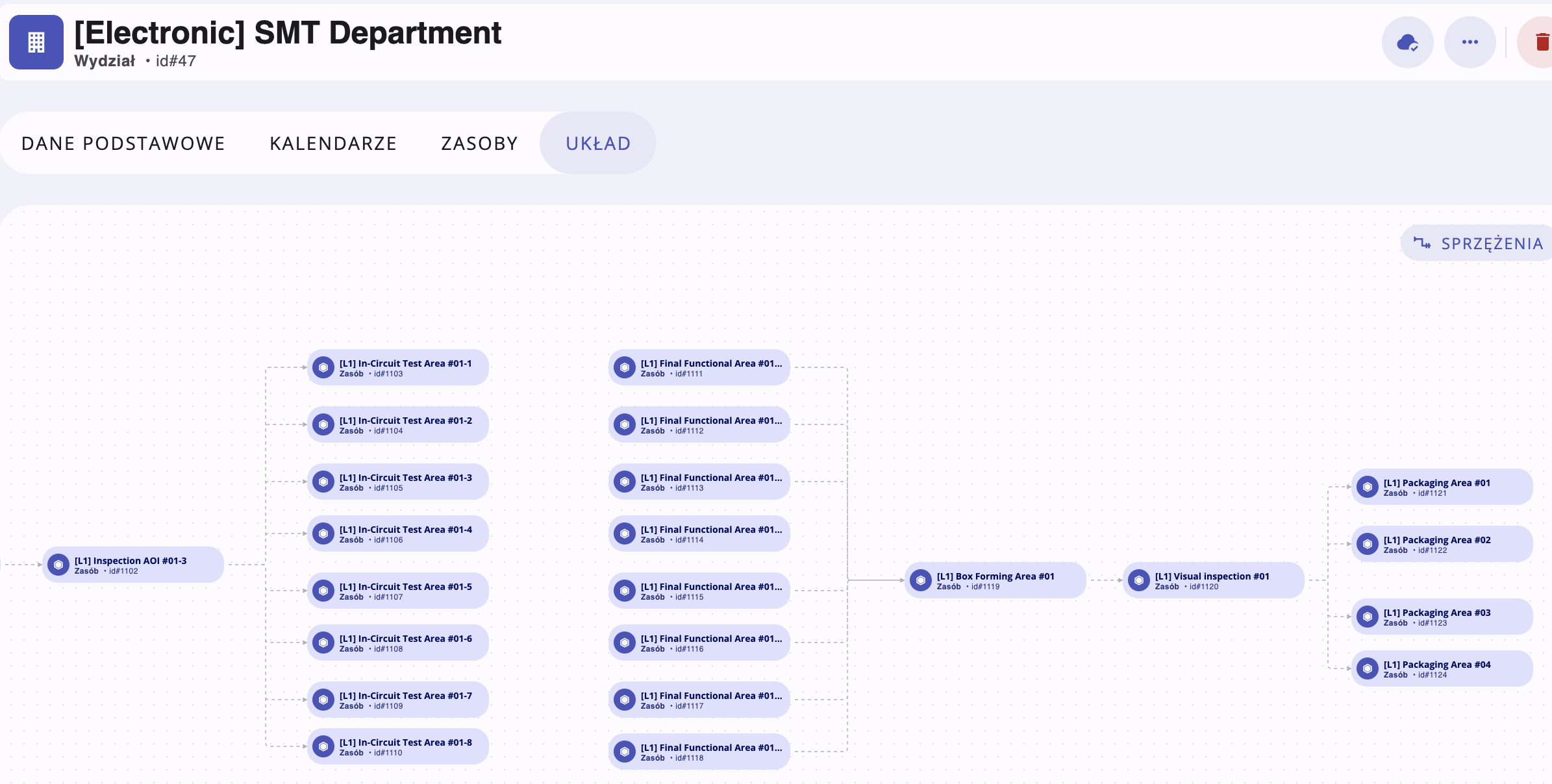

WE WILL MODEL ANY PROCESS

HAL can model absolutely any production process, in any industry, using standard functionalities or creating its own modifications. HAL uses the most modern algorithms available on the market, including Nobel Prize winners.

Powerful functionality as standard

Possibility of modifying the system

Proven algorithms

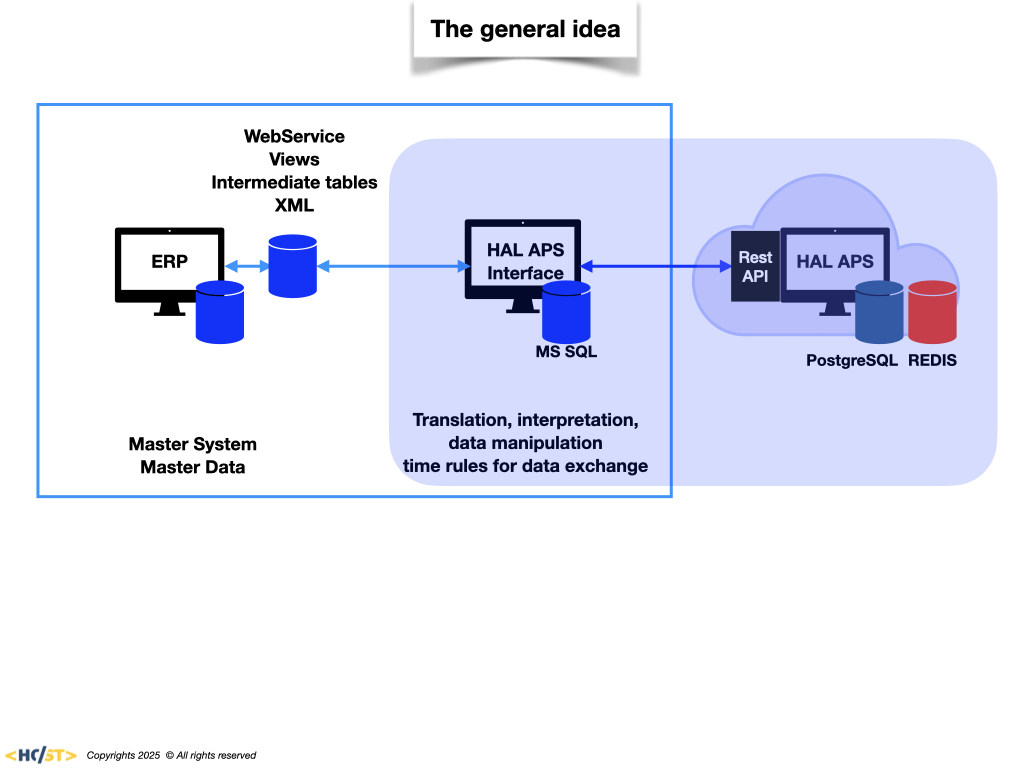

DATA EXCHANGE WITH ANY ERP, MES, CMMS

HAL APS can exchange data in real time with any number of ERP, MES, CMMS, SCADA, etc. systems.

SAP, D365, IFS, INFOR, Oracle, COMARCH, SOFTLAB itp.

REST API

XML, intermediate tables, Views, WebServices, bus data

ULTRA FAST

HAL is incredibly fast. He can recalculate the schedule as many times as you want, whenever you want. Since he's that fast, you can make him work really hard by giving him really hard puzzles to solve.

FAst

You can schedule a whole pool of orders or just one order

Another dimension of simulation

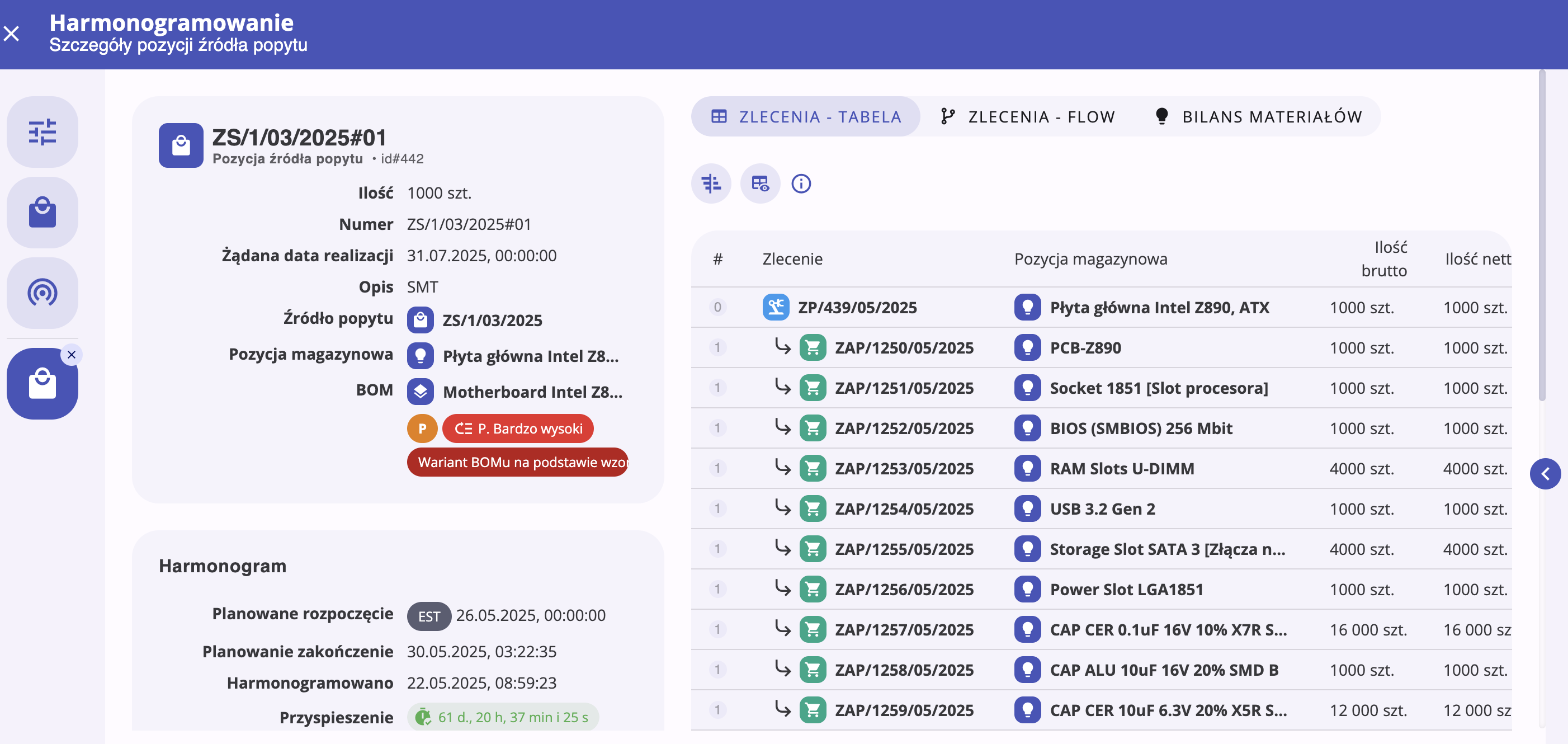

COMPLETE SCHEDULE THE FIRST TIME

HAL APS provides a solution to the planning task the first time, with a single click of the mouse. This is a huge competitive advantage, because most APS systems generate exception messages, conflicts that the planner has to resolve manually or through simulation. The planner usually simply does not have time for this.

schedule for the first time

zero exception messages

no conflicts

zero material

deficiencies

zero congestion, maximum use of bottlenecks

VARIATION MANAGEMENT

Production management is like a game of chess, you have to predict several moves ahead without being 100% sure they will happen. It's only a matter of time before you have to make difficult decisions quickly because material didn't arrive, a machine broke down, the flu has laid off employees, etc. Variability support in HAL is standard. The winner is the one who uses the best solutions and can react to changes quickly. HAL can independently choose the right algorithm and calculate all combinations, ensuring the schedule result the first time. We leave exception messages to the systems of the previous era.

managing supply chain variability

responding to unplanned events in production

the possibility of quick changeover of production

more automatic algorithms available

AI ON BOARD

The complexity of what happens in production can be gigantic. Production planners often have the impression that the number of combinations is approaching infinity. That is why we support cognitive processes with machine learning algorithms, so that the planner can focus on what AI cannot yet do. In some factories, the unit time of an operation depends on many variable factors and obtaining it during snapshot observation is impossible. HAL APS uses machine learning to learn the truth about the times of technological processes.

HAL APS stores historical data

Historical data is used to train the model

ENERGY USE OPTIMIZATION, CARBON FOOTPRINT

In recent years, the price of electricity has increased significantly and will probably increase even more. On the other hand, EU regulations require us to provide information about the carbon footprint (CO2 equivalent). HAL APS can prefer resources with lower energy consumption and/or carbon footprint in the scheduling process.

Scheduling with reduced electricity consumption in mind

Optimization of consumption of other media: gas, water, steam

Eco-friendly scheduling - reducing your carbon footprint

"HAL APS is the real answer to why you can stop scheduling production in MS Excel."

Janusz Pieklik

"I haven't seen a better APS on the market so far. It's a real step forward towards digitalization"

Mike Smith