PLANNING

HAL also offers you medium and long-term planning. It can profile seasonality based on safety stock or cover stock calculation. It provides information on ATP.

MRP AND CAPACITY RESOURCE

HAL simultaneously balances material requirements (MRP) and production capacity. One step instead of several, one coherent schedule instead of two, it is the only system that has such advanced functionality.

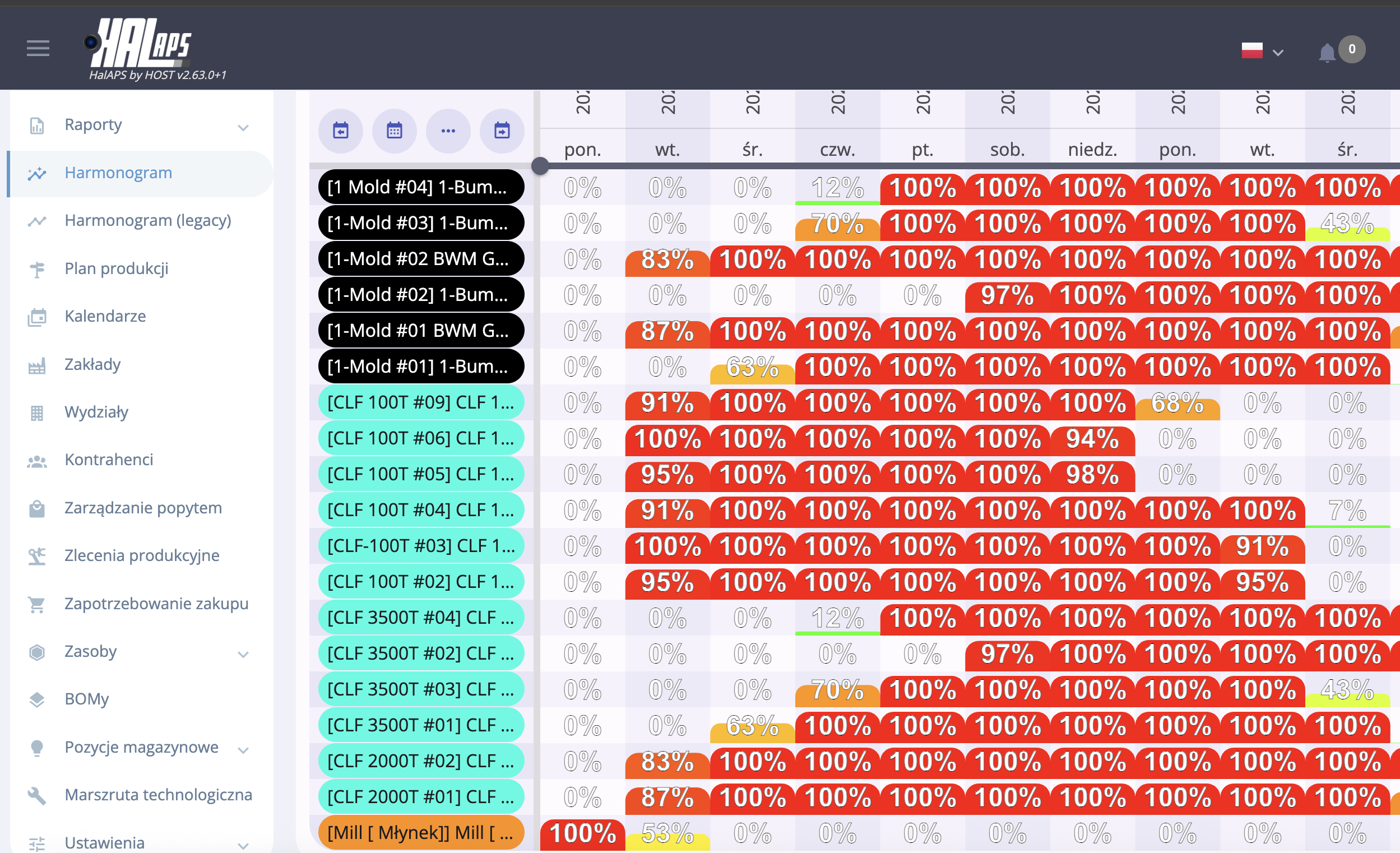

RESOURCE LOAD CHART

HAL provides information about the load of any resources in any time horizon. You can check the load of resources in a plant, department, cell, single resource. You can also simulate what would happen if you started overtime or a second, third shift, an additional day of work, hired more employees, started a process in cooperation.

CALCULATION OF THE NUMBER OF RESOURCES

HAL, when generating a schedule, can calculate the optimal amount of resources. It is always the case that above a certain number of resources, e.g. people on an assembly line, the efficiency increases minimally, or does not increase at all.

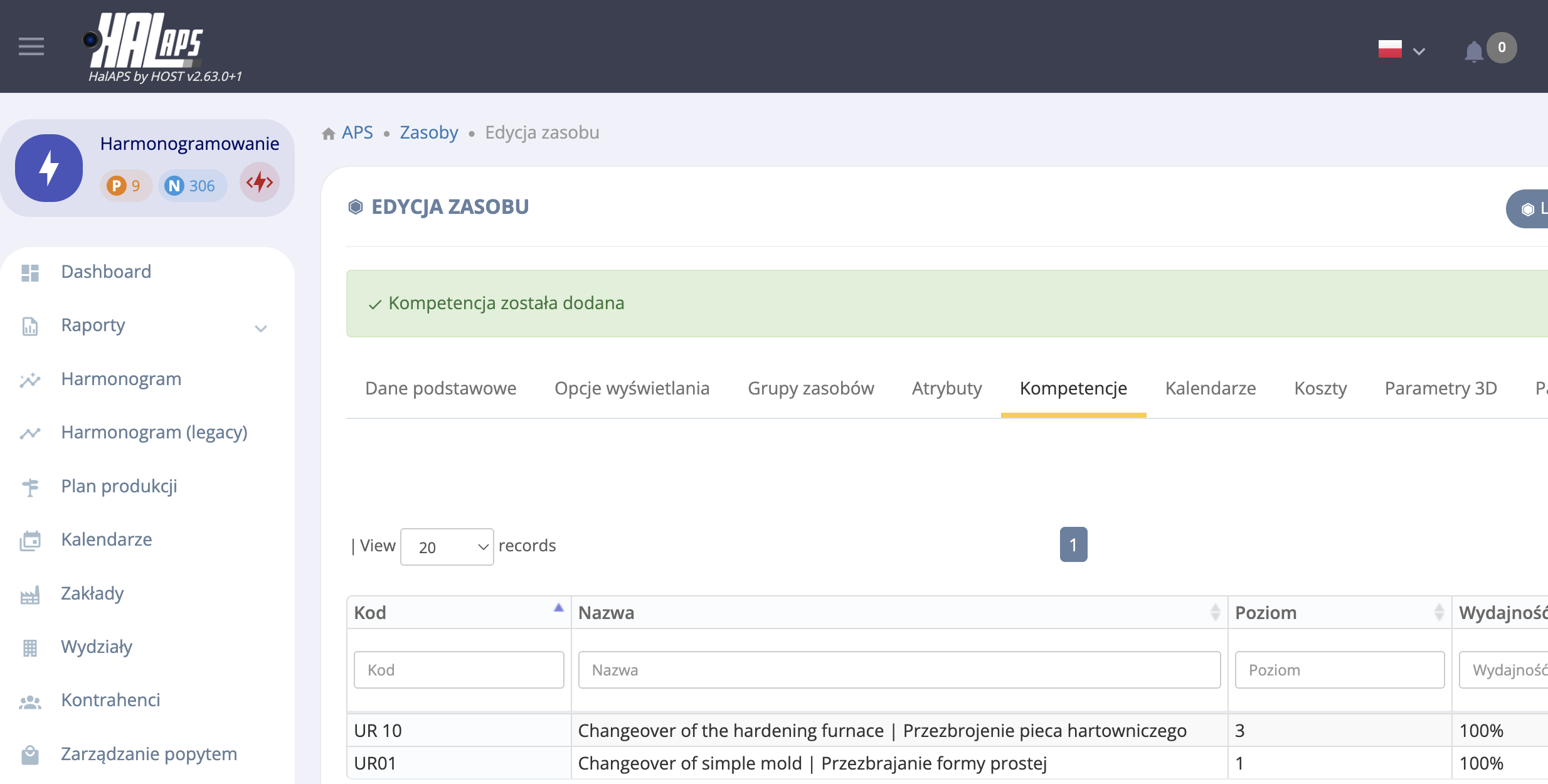

SKILLS MANAGEMENT

HAL APS can optimally utilize the competencies of any resource. Competency management is not limited to human resources. Competencies can be promoted or degraded. A given skill can be performed by an employee or machine with varying efficiency. Competencies have a wide range of applications.

RESOURCE SELECTION ASSISTANT

If you have selected resource A, you must select tool X or Y. This is a unique functionality that allows you to create dynamic resource selection rules. It can be used for operators. For example, if an employee is at work for the first time, automatically assign him a leader, i.e. an employee with high competences who will train him for 15 minutes. One-time or cyclical operation.

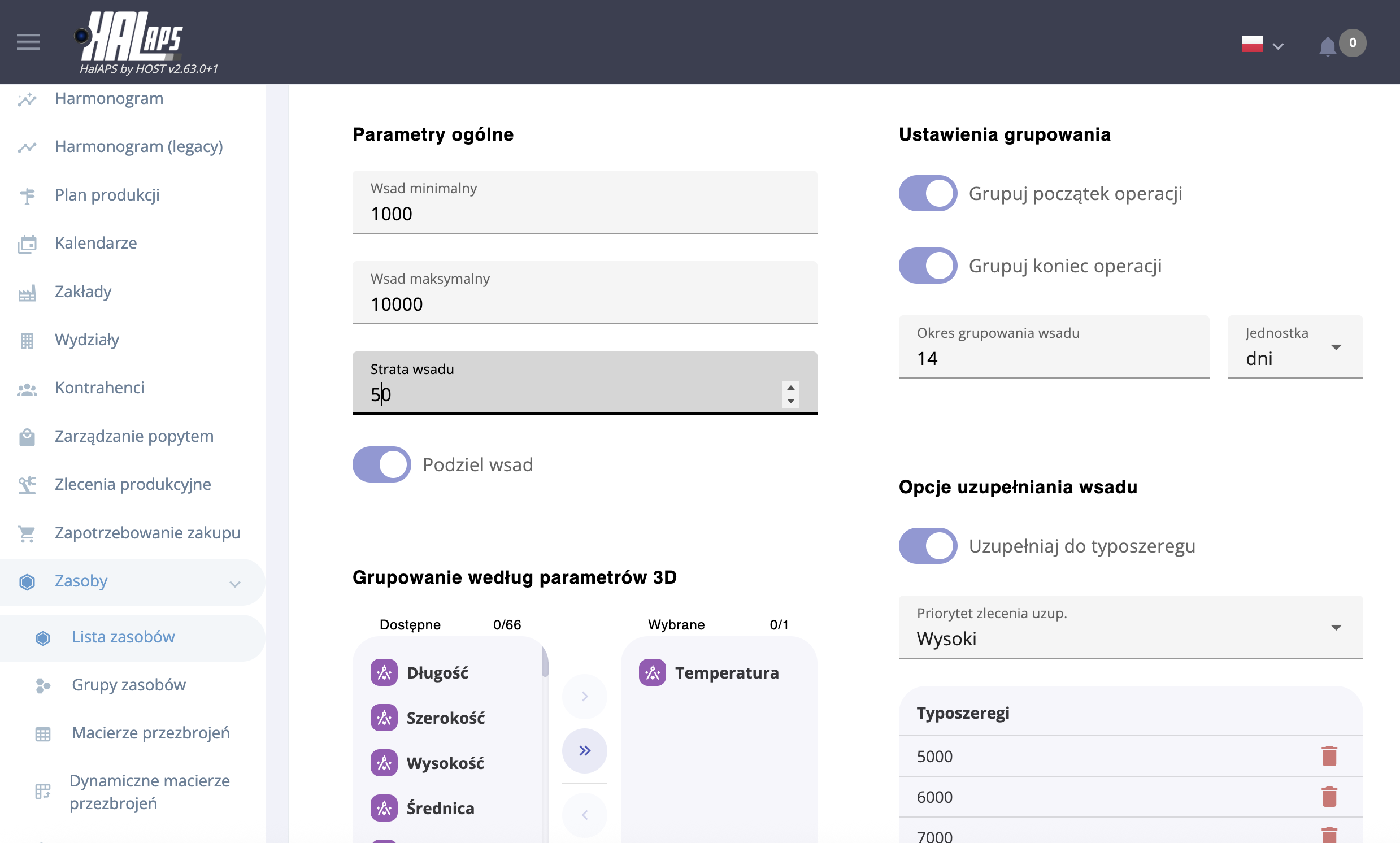

BATCH PROCESSES

The use of furnaces, mixers, paint shops, galvanizing tanks, silos, mills requires different scheduling algorithms. Optimization of the use of input resources, input losses, changeover times is crucial in process production.

CONTINUITY OF BATCH

The produced input often cannot be mixed with other input. HAL APS can identify the input and provide it with a traceable flow in subsequent processes. Mixing of cosmetic, pharmaceutical, food fillings, dough masses must be strictly controlled or is prohibited.

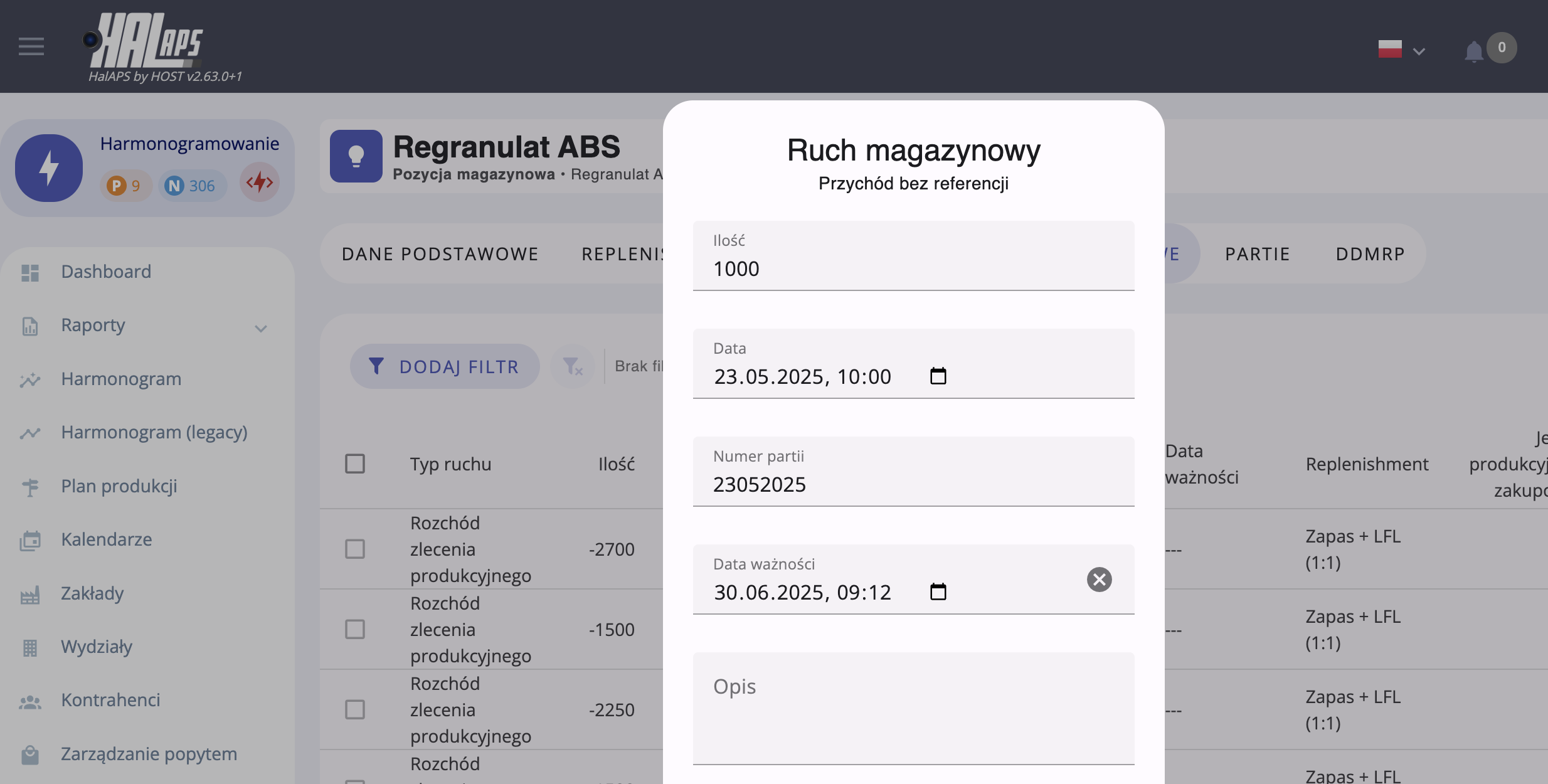

EXPIRATION DATES, BATCHES, SERIES

Scheduling production with expiration dates of production or purchase batches is a real challenge. But what if I told you that HAL APS can manage expiration dates of materials that are not yet in stock? HAL is truly unique algorithms.

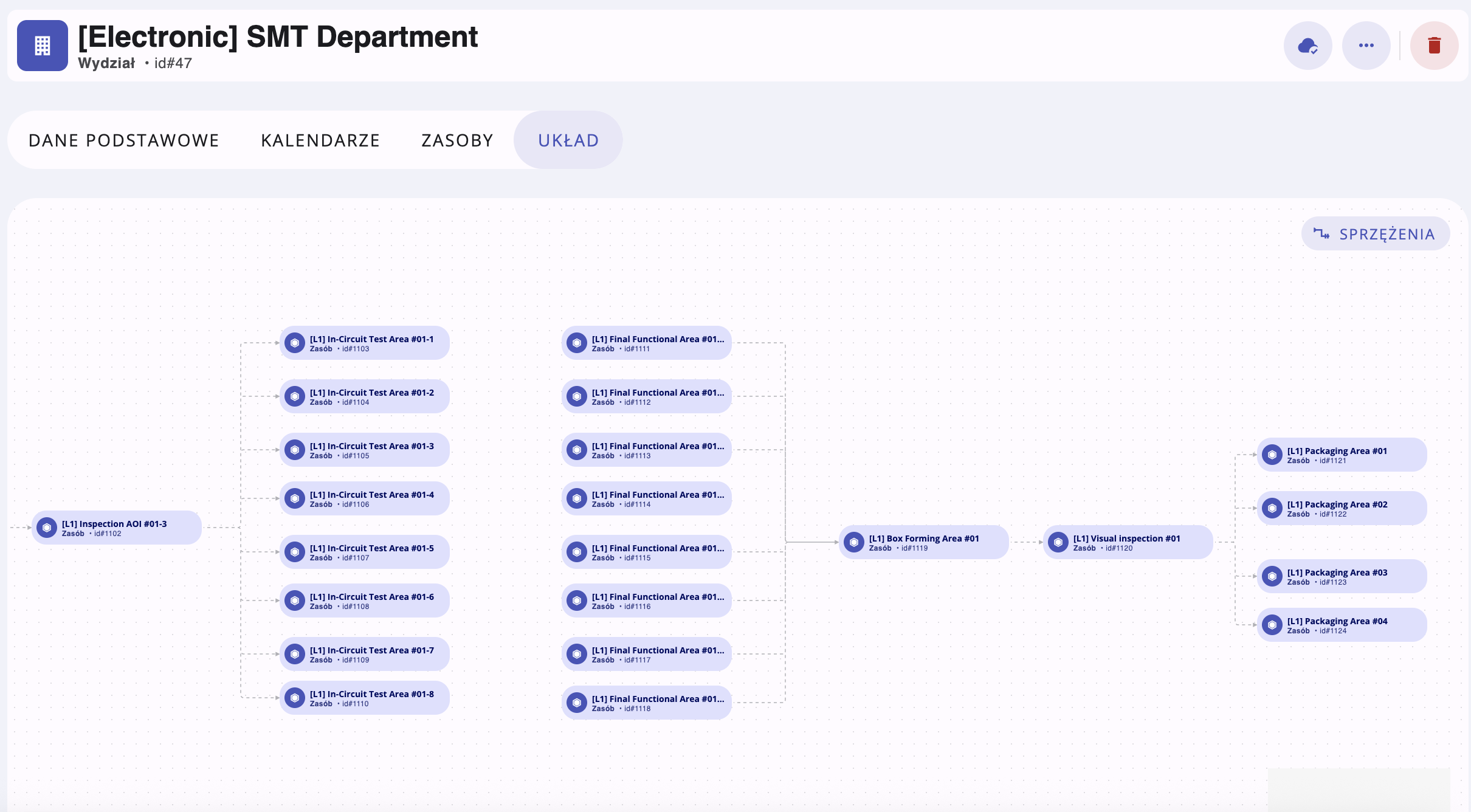

TECHNOLOGICAL LINES

The layout of the shop floor and the physical arrangement of the machines are important. To allow an employee to work simultaneously between two workstations, they must be close together. Moving materials between resources is sometimes impractical due to distances.

MTO - MAKE TO ORDER

Full control of production timeliness, increasing OTED - on-time deliveries. HAL APS always responds with a specific sales order execution date. HAL assumes ZS variability.

MTS - MAKE TO STOCK

Production to stock is a consequence of an internal order which initiates the need to meet the forecast, build stocks for promotions, seasons, in order to increase the level of service. Production to stock can create reservations.

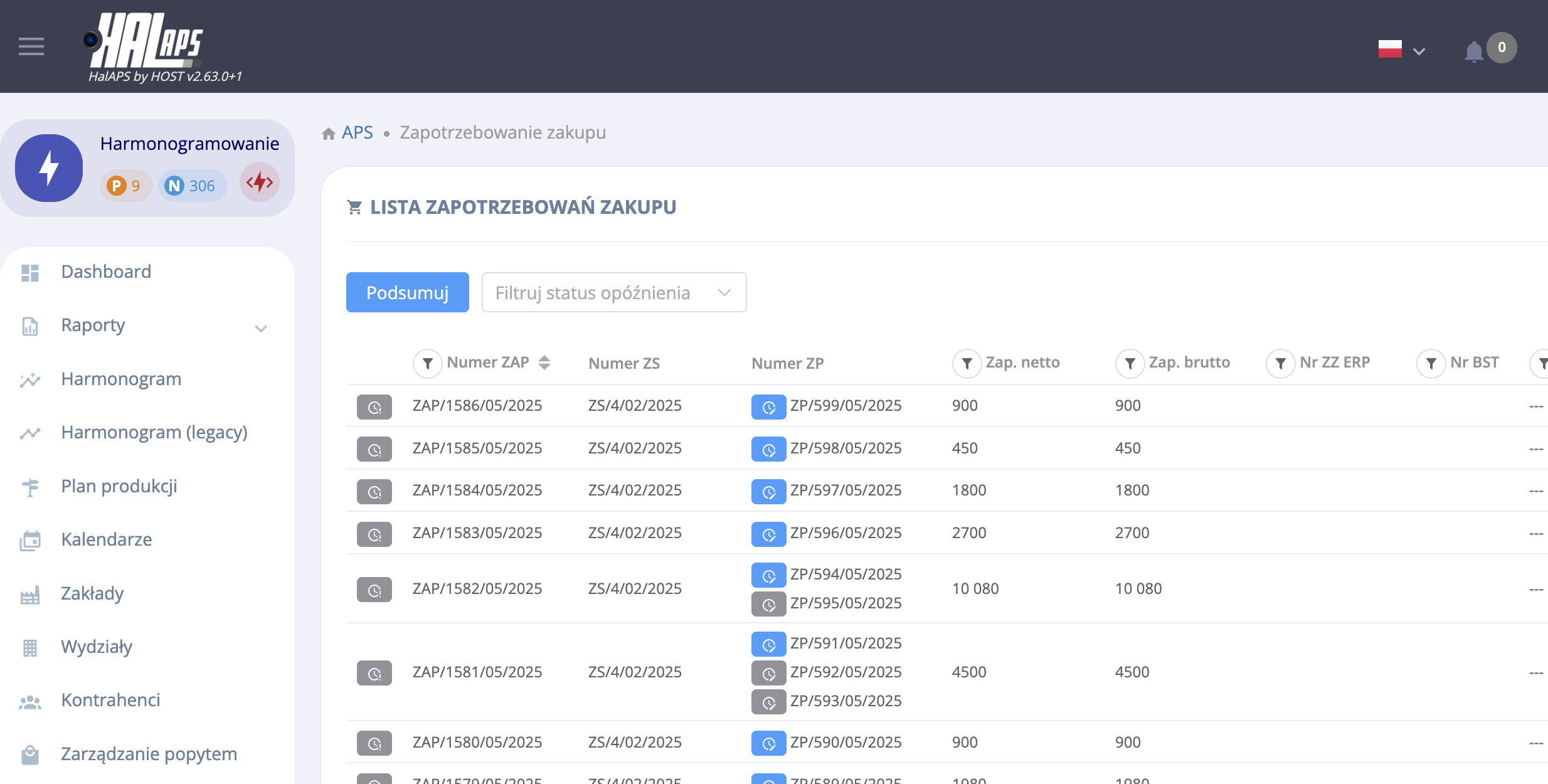

PURCHASE REQUIREMENT

HAL APS automatically generates purchase proposals and sends them to the ERP system. This is because HAL APS can balance materials with precision to the second. Purchase requisitions are sent to the ERP system. Orders are created in the ERP system and confronted with the demand.

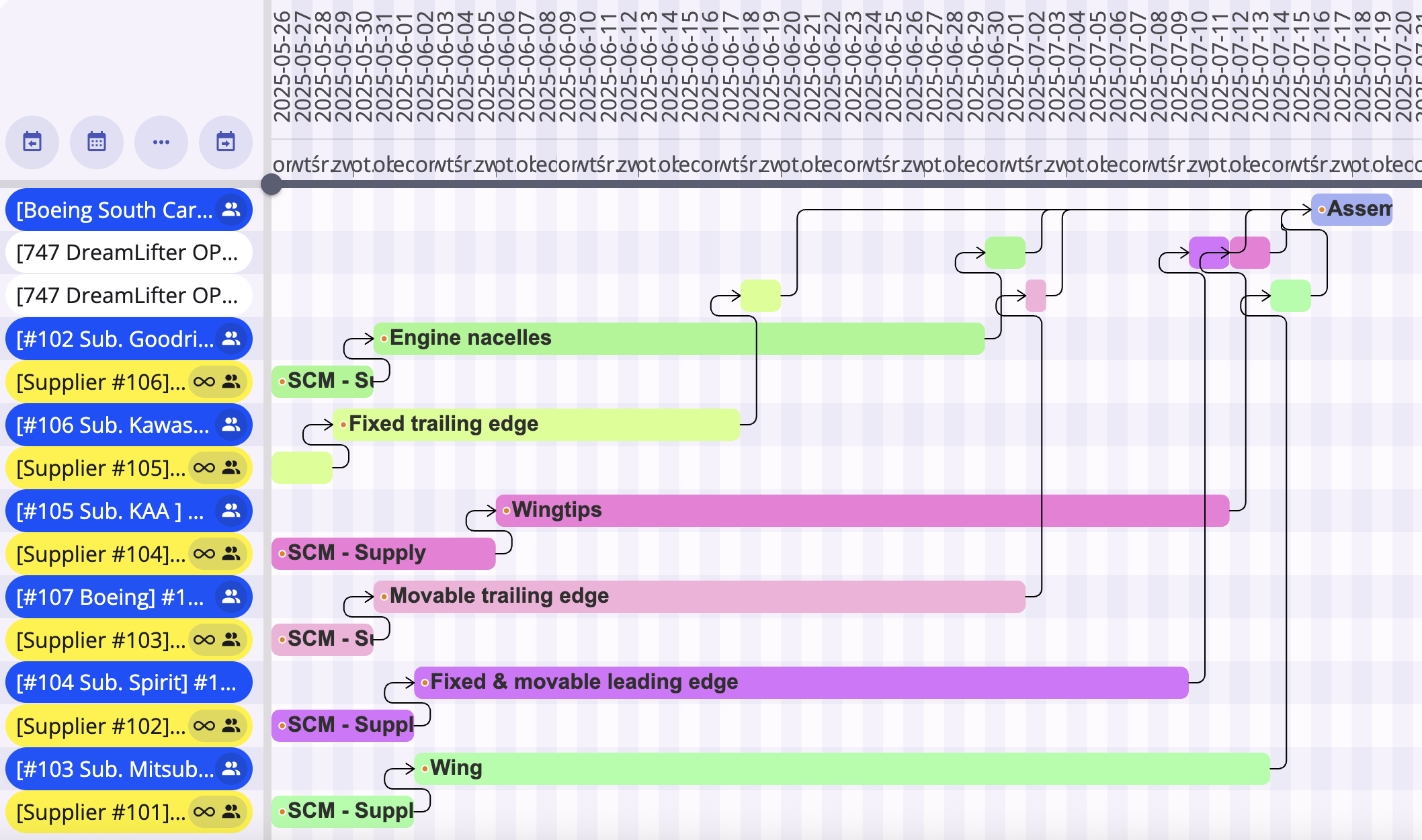

SUBCONTRACTING

HAL APS will precisely plan technological operations performed in cooperation. It can also plan transport to and from the cooperator. We can model the supply chain of plants operating on different continents in different time zones, with different holiday calendars.

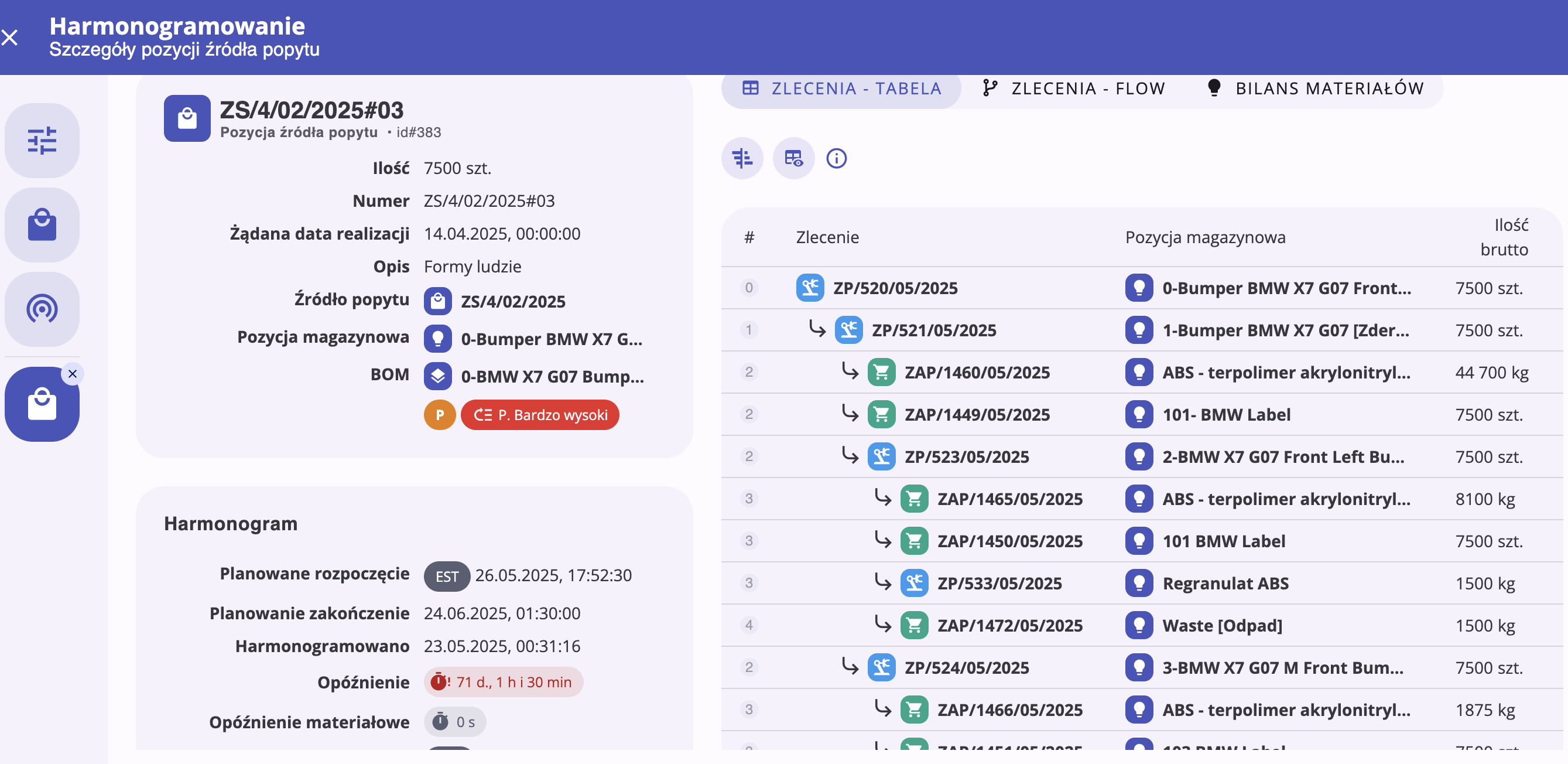

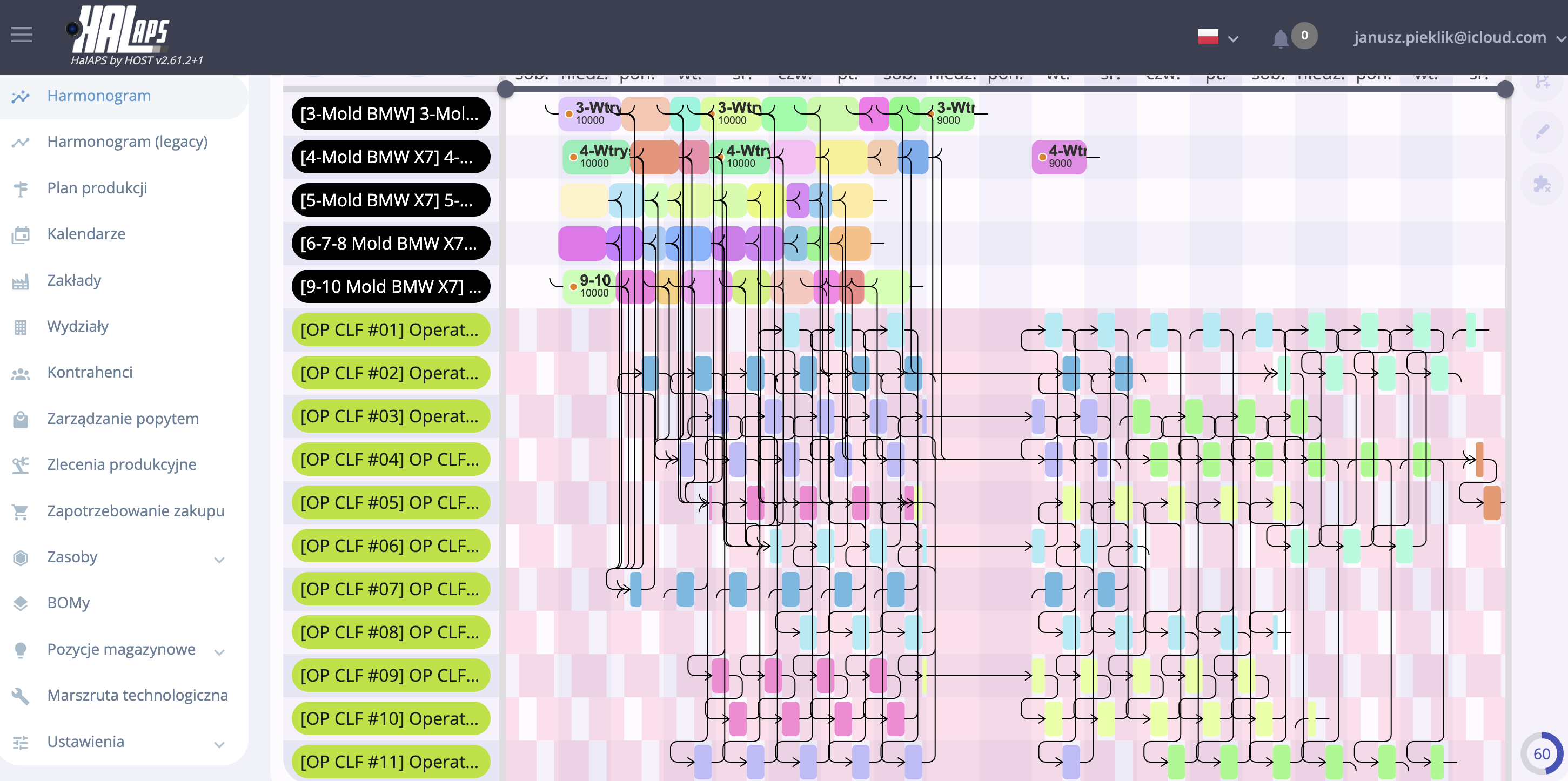

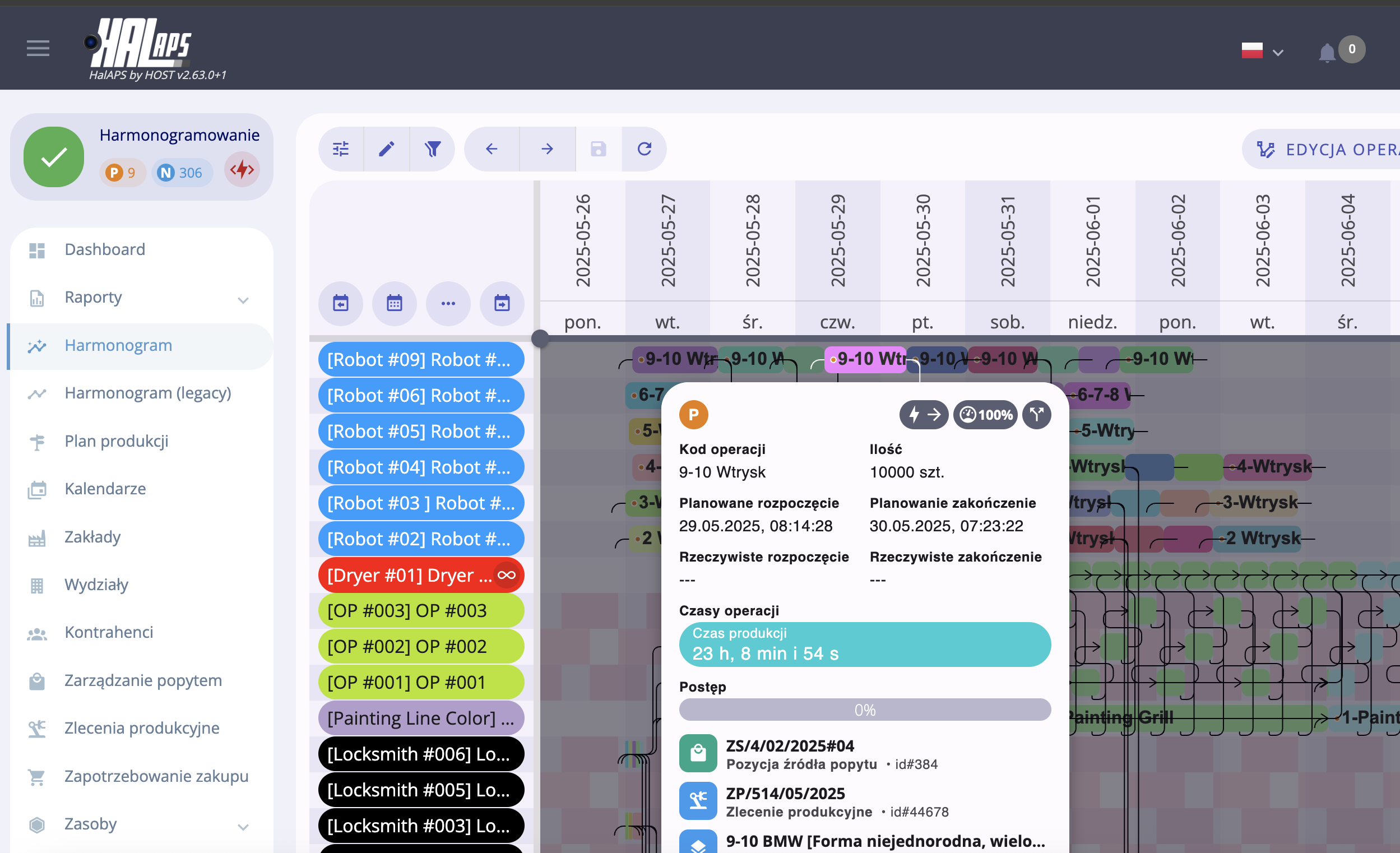

SCHEDULING

HAL APS is designed to effectively solve production problems in an environment of high variability of everything that occurs in the supply chain and internal factory processes. HAL has the tools to quickly respond to simple and nightmarish surprises.

REAL RETURN ON INVESTMENT

Imagine that by more optimally arranging the queue of tasks to be performed, you will free up only 10% of production capacity. With a turnover of 100 million, you can earn 10 million more, in the same time, with the same resources. Sounds interesting?

And what if we free up 15%, 20% or 30%?

INDUSTRY KNOW-HOW

HAL offers you industry Know How as standard. The Best Practices implemented in the areas of metal production, machinery, electrical engineering, hydraulics, plastics processing, furniture, pharmaceutical, cosmetics, chemical, construction ceramics, food, feed, reinforcement, automotive.

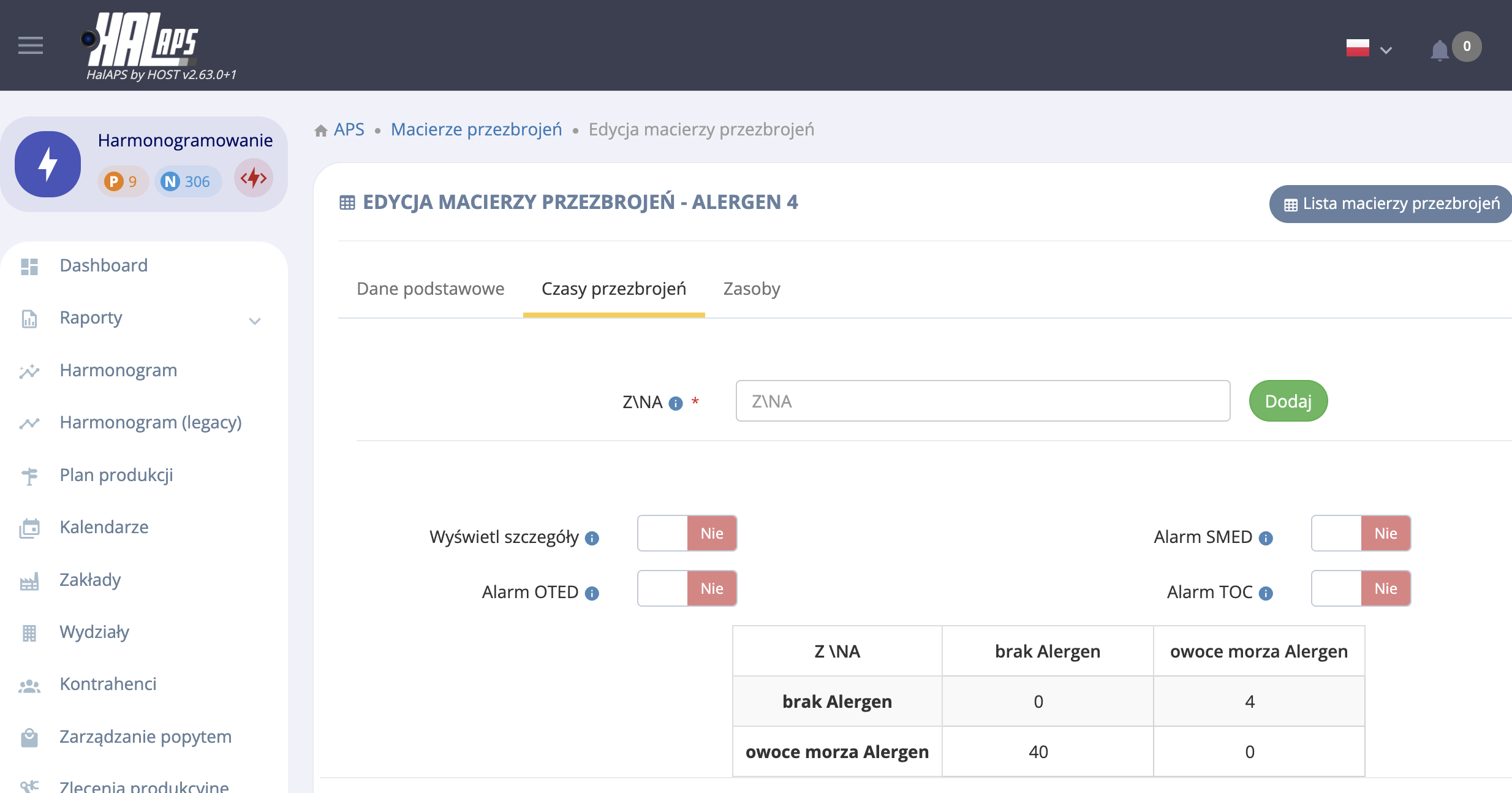

MINIMIZING CHANGEOVER

Minimizing the number of changeovers is the key to cost-optimized production.

Fewer changeovers mean lower planned and actual TKW.

SETUP MATRIX

HAL APS can analyze the production sequence and change the changeover time. The actual changeover time is a combination of the time depending on what was produced before and what is to be produced now. It is also important what tooling, tools were before and what will be now.

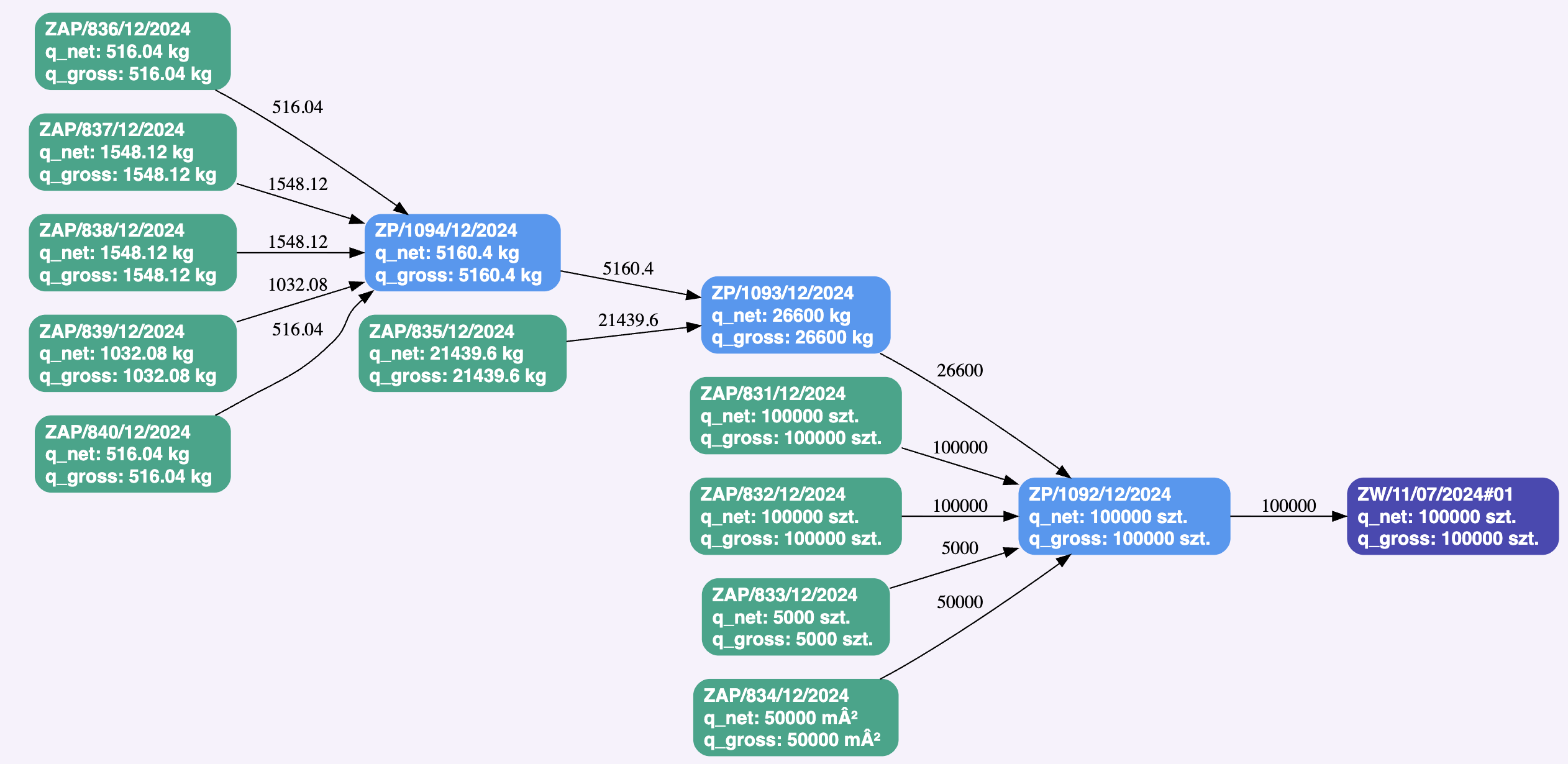

CLOSED PLANNING LOOP

HAL APS balances everything from demand to supply. Demand can be a forecast, a sales order, production to stock, or a sales offer. HAL will balance materials by creating purchase requisitions, material reservations, and at the same time balance production capacity by creating production orders. Purchase requisitions will be coordinated with purchase orders.

PRODUCTION PROGRESS

You can observe the production progress in real time. HAL enables the presentation of production progress in a Gantt chart, as well as in a tabular form. Production progress is information that HAL is fed with from the MES, SCADA, OPC or ERP server.

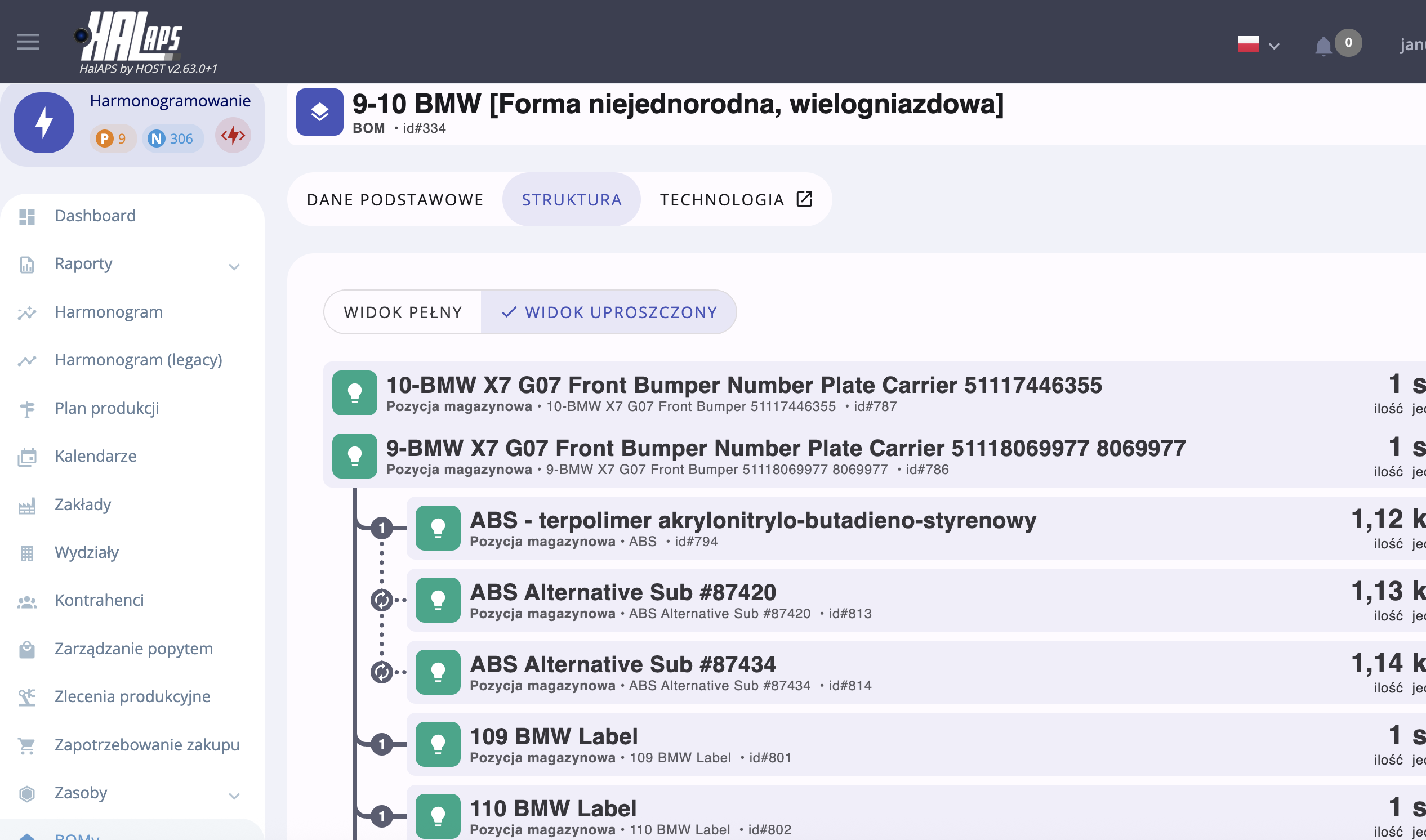

SUBSTITUTE

The handling of substitutes is fully automatic, the decision to use a substitute is made in the scheduling process. You can define any number of substitutes that HAL will manage in an unattended manner. A substitute for a purchased item can be a manufactured item and vice versa.

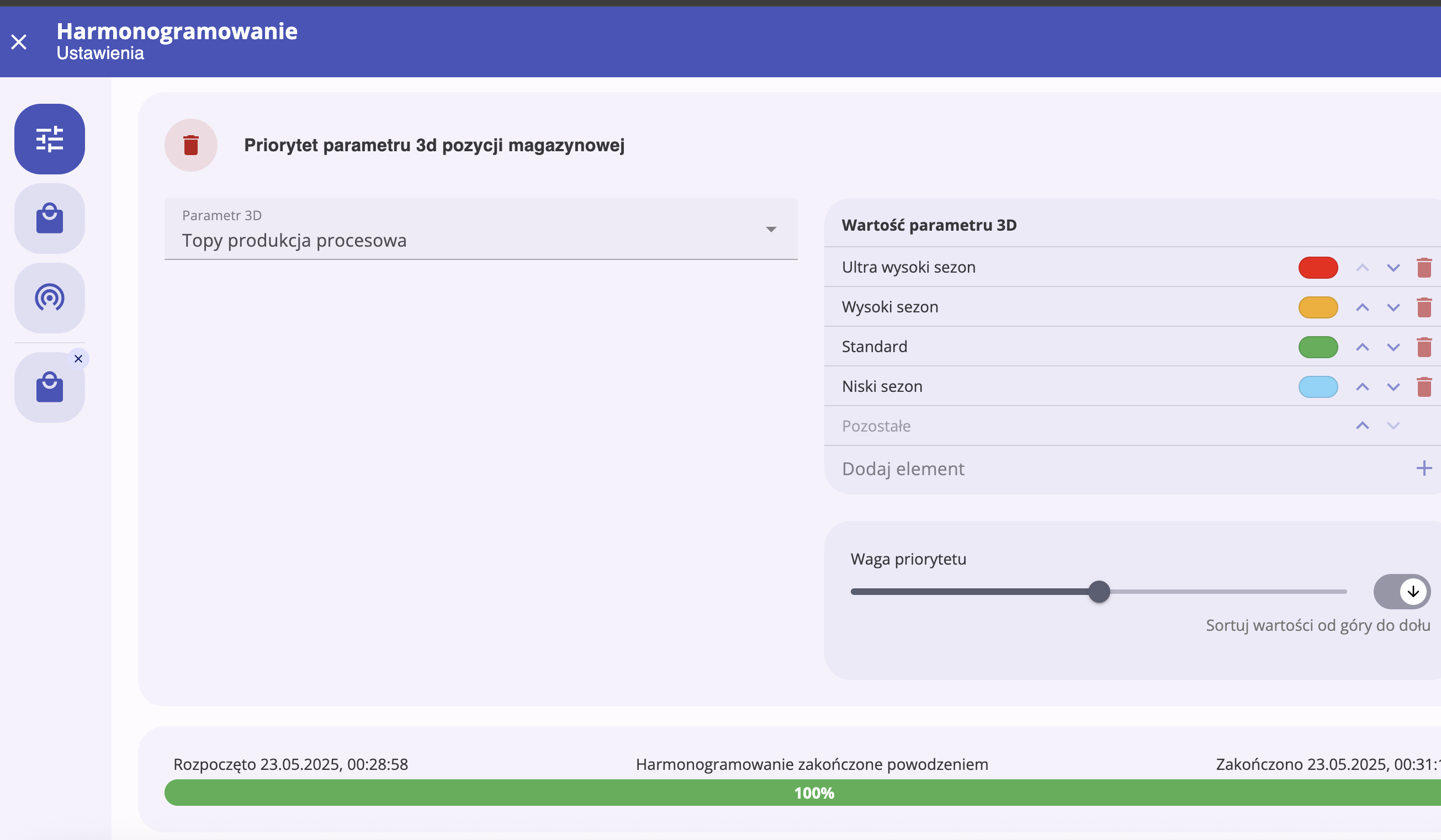

ANY SEQUENCE

You can create any definable sequence of tasks for orders to schedule.

From white to black, from creamy to chocolate ice cream, from watery to heavy cream, from tops to basics, from high penalty to low, etc.

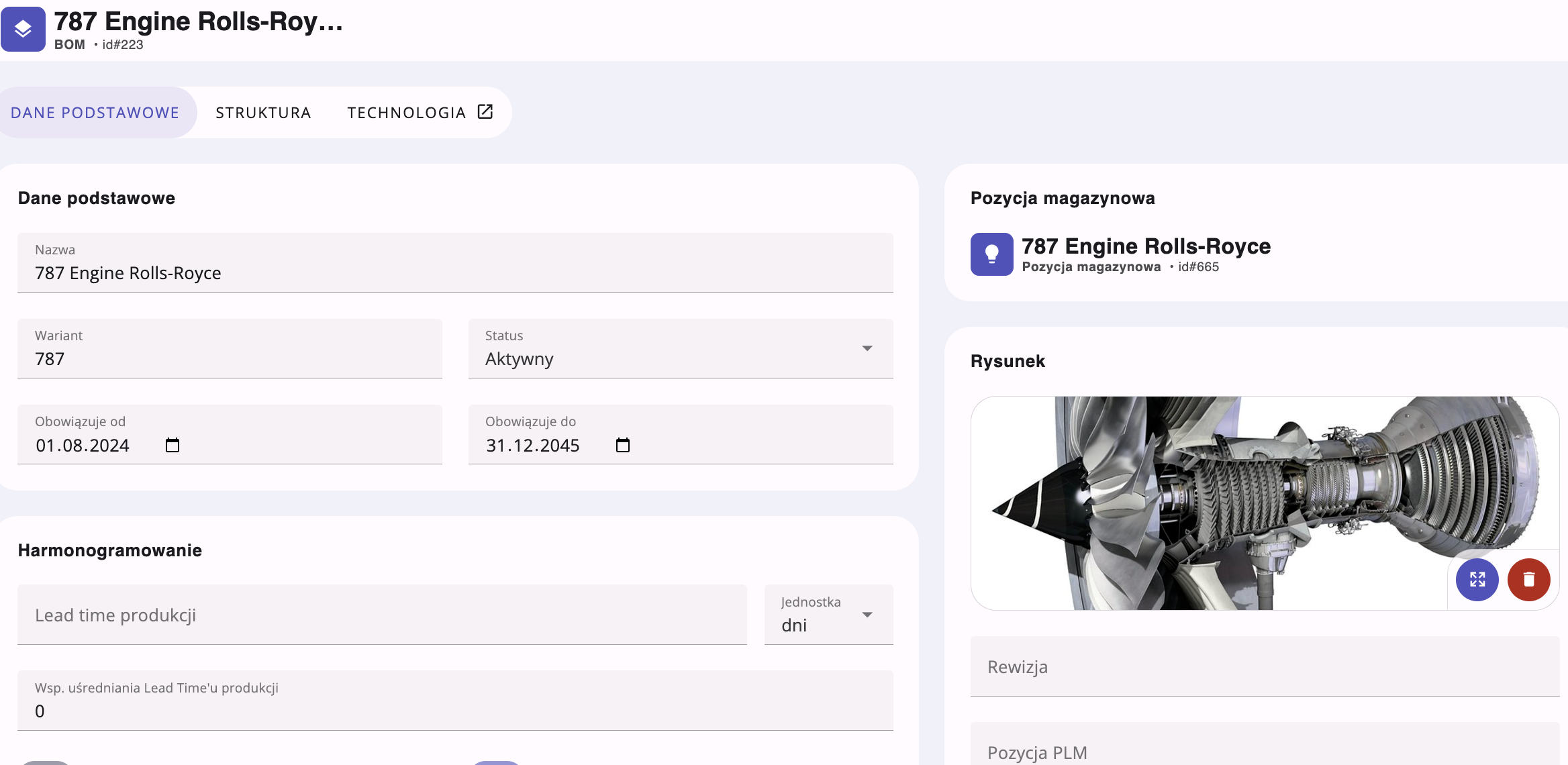

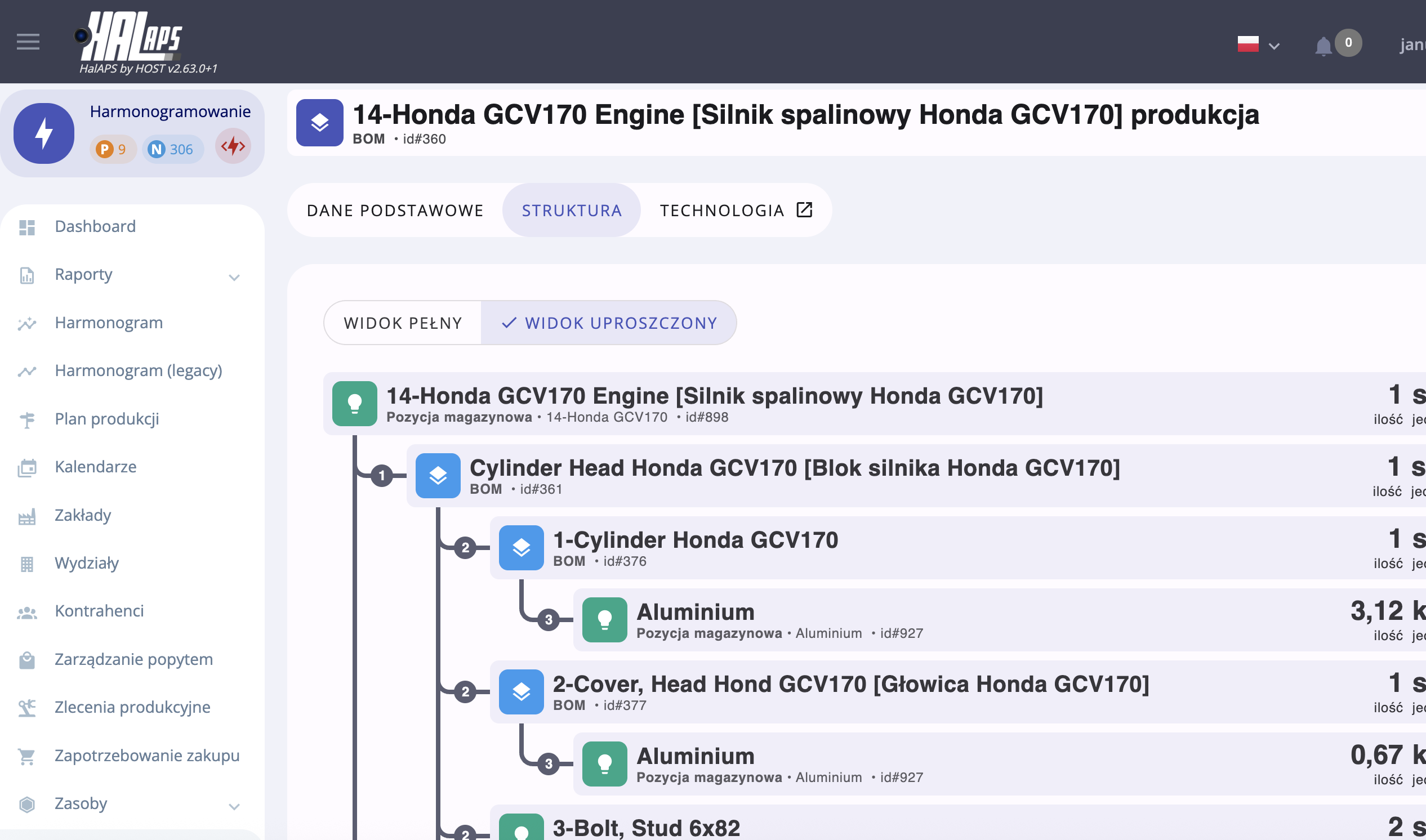

MULTILEVEL BOM

HAL APS can build complex, multi-level BOMs characteristic of complex products. Unlimited number of levels, unlimited number of semi-finished products, unlimited number of versions / revisions. Linking to PLM, CAD, drawing item.

MTF - MAKE TO FORECAST

HAL APS gives you the ability to manage a hybrid strategy, which consists of observing the consumption of the forecast based on the incoming sales orders. It is a combination of MTS and MTO.

MAINTENANCE SCHEDULE

HAL APS enables scheduling of planned repairs, inspections, and services. Planned maintenance work requires the shutdown of resources and the use of alternative resources or waiting for the completion of planned activities.

REVERSE BOM

HAL APS can schedule product structures where more than one semi-finished product, finished product can be obtained from one material. This is characteristic for regenerative production (automotive), meat and poultry plants, the wood industry, plastics processing, etc.

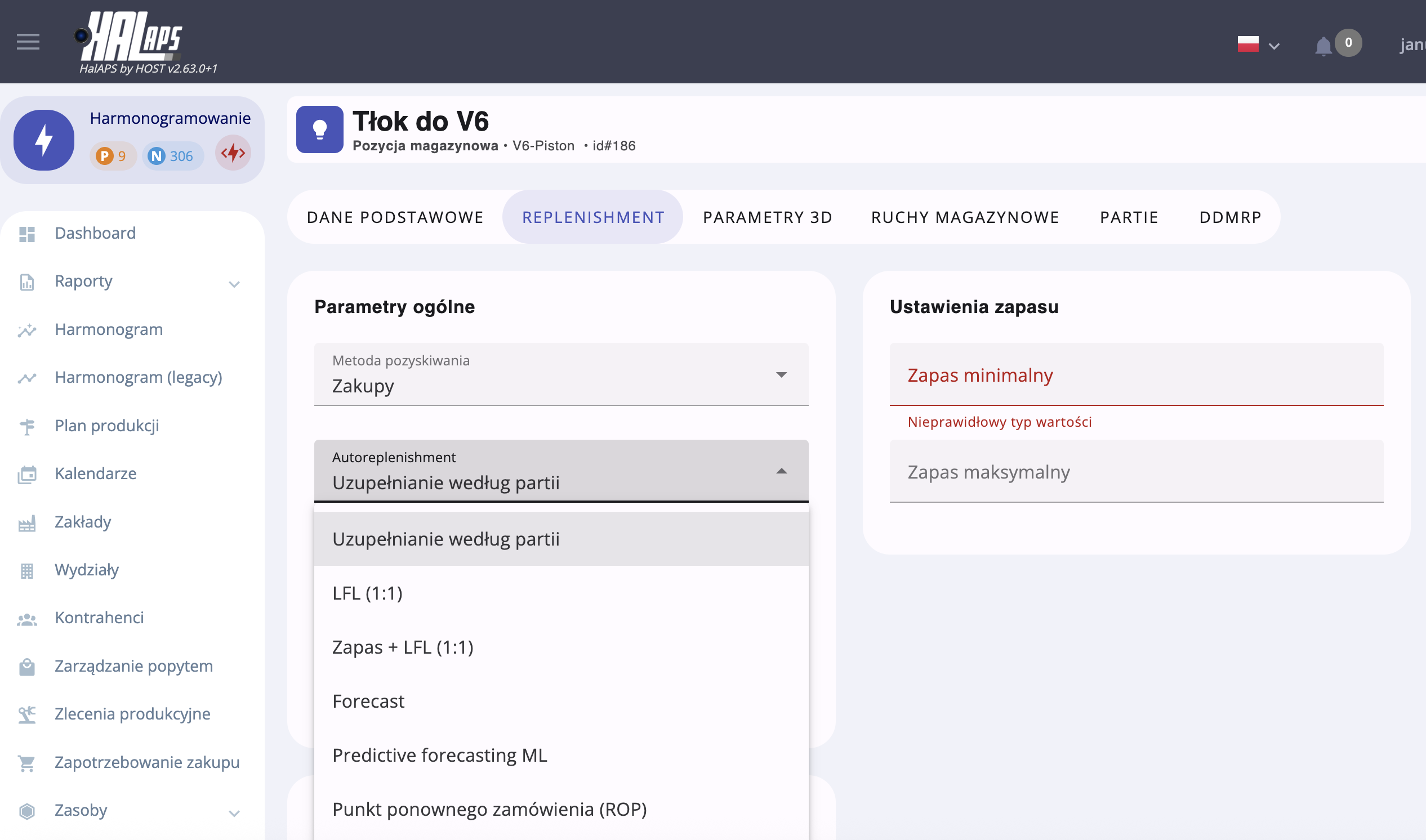

AUTOREPLENISHMENT

HAL APS can manage auto-replenishment of production and purchase items. Project replenishment 1:1, stock + 1:1, batch replenishment, reorder point, target stock level, forecast, Machine Learning, DDMRP, batch replenishment orders.

Stop guessing, start planning. Winner takes all, the winner is the one who has reliable information here and now.

Ewa Parker